Common Issues & Suggested Solutions

We record the most common problems we come across everyday along with some suggested solution.

The rising dampness is without any doubt one of the most common problems in buildings. The water naturally present in the soil rises up along the foundation, until it reaches the vertical walls, appearing in their lower side.

All building materials such as mortars, bricks, concrete etc. are characterized by a certain degree of porosity, that is the presence of air in them. All the areas where the air is present are called “capillary” and actually represent the way that water always follows to rise up on the materials.

The rising dampness after years can cause more or less severe damages to the walls: aesthetic damages or injuries, such as stains and moisture halo, detaching of paints, moulds and efflorescences; but also damages to the structural level: detachments of plaster parts, chalking and loss of consistency of materials.

Unlike what is generally perceived, is not the water the principal cause of these damage, but the minerals dissolved in it. These salts are naturally present in soil and in building materials and, once in contact with water, dissolve themselves inside it, becoming a unique solution. But when the water evaporates, these salts remain in the pores of the masonry, crystallizing and greatly increasing their volume.

After some time, these salts will come inevitably to saturate the masonry, thereby exerting a pressure that causes the detachment and crumbling of the building materials. The classic example of this phenomenon is the release of saltpetre from brickwork.

To prevent the capillary rising of dampness is necessary to provide an adequate waterproofing of the entire foundation structure of the building: keeping dry the base of the structure, this will remain so throughout its complete height.

Where, however, that sealing was not realized during the construction phase of the building, to solve the problems related to rising dampness, it’s possible to proceed with different types of intervention.

Solutions

Retrieval System with Microporous Natural Plaster Dehumidification

First the soluble salts must be stopped not to be inserted into the masonry with water mixing mortar or by the rising damp process. By using suitable mortar or liquid you can drastically reduce the penetration of salts in the masonry.

Then you the entrance of moisture must be treated by using specific macroporous plaster, which allows for dehumidification of masonry (ie the quick passage of water vapor within the masonry and evaporation into the environment).

Retrieval System with Repellent Resin

In the case where it can not be applied the previous method for either appearance purposes, lack of space, etc, the problem of moisture can be treated by injecting a water repellent resin into the bottom of the wall evenly over the entire surface. The resin enters in all the facade of the masonry, creates a barrier that prevents moisture to enter to the wall.

Reinforced concrete is a conglomerate made up of concrete with embedded steel bars inside, characterized by high mechanical strength and therefore widely used in the construction industry. Also if strong and durable, it is subject, such as all building materials, to the effects of degradation due to weathering exposure, structural movements or to exceptional events such as earthquakes.

Anyway, the most common deterioration factor remains the rust formation on the reinforcement steel bars, caused by the penetration of oxygen (via air or dampness) up to the surface inside of the armature iron. The rust increases the volume of iron, resulting in swelling and detaching of the concrete, which “break” the surface continuity, thus reducing the structure mechanical strength.

Restoring Reinforced Concrete

After oxidation of the reinforcement is likely that part of the concrete covering the steel to detach itself completely from the remainder of the structure. In these cases it is necessary to restore the surface, apply an appropriate treatment for restoration and protection of the rods and restoration of missing part of concrete, using products with sufficient mechanical strength.

Solution

For the repair of reinforced concrete must be checked: (a) the longitudinal and transverse reinforcement showing oxidation and loss of the original section and (b) the structure of the concrete.

In general are proposed the following steps, which outlines the type of procedure:

- Remove all weathered concrete sections and full disclosure of corroded reinforcement and cleaning for the removal of rust (mechanically or with the use of special cleaning rust).

- Coat with layer mortar corrosion protection for reinforcement bars that have experienced oxidation and the adjacent concrete surfaces.

- Apply mortar to repair concrete thickness suitable for the rehabilitation of deteriorated concrete and mortar for fine finishing application for protection, smoothing and finishing.

The proposed final solution must be suitable for seismic areas with high chemical and mechanical resistance, creating a final smooth surface, without cracks for further coverage and coloring.

It could be also applied protective barrier coat using special cement – waterproofing products.

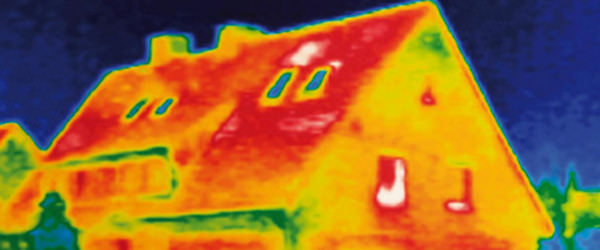

The realization of any kind of structure must have, as its final goal, the achievement of the building quality in order to live and use its spaces. One of the most important aspect is certainly the thermal comfort of the indoor environments, that can be reached through a correct realization of thermal insulation, to limitate the heat losses.

The heat in fact moves naturally from the areas at high temperature to the areas at a lower temperature. For this reason, during winter season, heat inside our houses tends to move outward, while during summer season heat tends to move inward.

An incorrect thermal insulation may cause:

-the formation of condensation and mould on the walls;

-a drop in the superficial temperature of the walls;

-a drop in the environments temperature;

-a low living comfort within the rooms;

-a rising in the costs to heat rooms.

Heat losses can be slowed down and controled using suitable insulative materials that, thanks to their characteristics, do not allow heat dispersion, allowing to have a stable and constant temperature and thus the living comfort.

A well thermal insulated structure allows a considerable costs saving for air conditioning and represents an environment with more comfort and therefore aperceived greater good living.

Solutions

Today there are many solutions either panels or thermoplasters that can give solutions to the problem of thermal insulation in exterior and interior surfaces.

There are a number of advantages that one must take into account in the selection of the first system and the second type (thermoplaster or thermo panels) . The choice should be made by the field of application (masonry easily accessible without barriers , etc) , the available thickness of application, type of surface ( brick , existing plaster etc) , if the construction is new or old , if soundproofing is needed simultaneously with the thermal insulation, the implementation time and more importantly , the total cost of insulation .

The solution proposed by EM4C is based on the use of thermoplaster or total insulation plaster (with cork shavings or granulated expanded polyester) depending on the needs of the project because it is very effective, easy to implement, fast, simple, hassle-free thermal bridges and mainly economic.

Asbestos is a mineral material characterized by a fibrous structure that, until a few years ago, was used in the building industry because of its high mechanical strength and chemical properties. Asbestos fibers are extremely thin, up to 1300 times smaller than a human hair, so they are extremely volatile and easily inhalable.

Because of the carcinogen city of asbestos fibers, its use has been outlawed since 1992. Law No. 257/92 lays down the terms and procedures for the disposal of inert and asbestos still present in buildings while M.D. 20/08/1999 and successive modification describe the procedure on how to encapsulate asbestos.

Systems for the encapsulation of asbestos usually consist on the application of resins and coatings that can totally cover the surface and fully encapsulate asbestos, completely preventing the dispersion of the fibers in the air.

Solution of Encapsulation Asbestos Fiber

Current European legislation on asbestos encapsulation and neutralization has three (3) types of permanent forms of asbestos encapsulation surfaces:

Type A: Encapsulation external surfaces

Type B: Encapsulation of exposed interior surfaces

Type C: Encapsulation of non- visible surfaces, internal and external, for the implementation of other interventions.

The encapsulation systems include:

(a) the introduction of an impregnating material to cover the fibrous matrix of the surface of asbestos and create a necessary bonding bridge for the encapsulating material and

(b) the application of the encapsulating material to completely cover the surface application to prevent the spread of asbestos fibers into the environment.

The proposed system must be certified in accordance with regulations UNI 10686 and has the following features:

- Easy and fast application

- During the recovery to be able to access the building interior

- Excellent results consolidation and integration of asbestos fibers

- Resistant to UV radiation and in all atmospheric factors

- Waterproof with excellent flexibility at both high and low temperatures

- Long life

The bituminous membranes are undoubtedly one of the most widely used technology for the waterproofing in positive thrust of roofing and foundation structures. Although they are characterized by a low cost and wide versatility, the bituminous membranes have problems that, in the long term, may even compromise the correct waterproofing effect of the sealing layer made with them.

Those membranes indeed, have a low and limited resistance to foot traffic, a very low elasticity (regardless of ambient temperature), an early deterioration in case of direct exposure to UV rays, also in function of their inevitable black color, which often causes an overheating of the insulation layer, with its resulting crack or even separation from the substrate below.

Considering that they are prefabricated materials, generally supplied in rolls, it becomes also problematic the treatment of critical areas such as vertical / horizontal joints and angles, expansion joints, or any eventual passers-by corps such as chimneys or vents exhaust ventilation: in all these cases the bitumen sheaths must be modeled, with an high risk, caused by the limited elasticity of the material, and with a considerable increase in working time.

A further problem with bituminous membranes is the high probability of making mistakes by of the applicator: during the so-called “torch” of the material is sufficient just one point where the sheath is not fully stretched and well settled to create a discontinuity of the insulating layer. Discontinuities that inevitably represent a possible point of access to water.

The bituminous membranes are also a particularly critical type of support if you want to cover them with different types of materials: the presence of oils and greases that characterizes the polymer matrix of membranes makes particularly difficult to achieve the proper anchoring bridge (both chemical and mechanical), especially if using materials such as acrylic or polyurethane resins. As a result, mostly in the restructuring projects, they should be removed entirely, forcing people to sustain costs arising from their proper disposal as a special waste category.

Solutions

Solutions without removing the existing bituminous membranes by applying a protective coating:

In order to seal and increasing the strength of the bituminous membrane a protective coating is applied designed to ensure proper adhesion. Then the surface could be coated with the material we choose.

Also the use of specific resins is possible, with the sealing, to cover the whole surface of the membrane, protecting it from ultraviolet radiation, allowing the possibility of dramatic decrease in the temperature of the bituminous membranes thus increasing the time of application, but also reduce the heat transmitted from the roof to the areas of construction (less use of air-condition).

Rust is a chemical compound of a reddish-brown color that is formed spontaneously on iron surfaces due to contact between them and the oxygen in the air or water. The chemical reaction that has been initialized causes the gradual deterioration of the iron surface, up to its complete disintegration.

The rust, without considering the aesthetic impact, also generates direct costs for the maintenance of iron surfaces, and indirect costs due to the inoperability of the areas concerned.

To remove and prevent the formation of rust, it is possible to proceed with its removal using a special rust converter and then to the encapsulation of the surface through a suitable encapsulating paint.

Solutions

The use of a specific solution allows full integration of the oxidized particles (rust). The material is able to break the bond between the chemical reaction of iron with oxygen and to “trap” particles that are responsible for the spread of rust, thereby preventing new formation.

After cleaning the surface of the steel, the surface may be covered for permanent protection against oxygen or water with:

1.With anticorrosive paint (two-component) , which with a thickness of only 2 mm creates an impervious and effective barrier to oxygen and water.

2.With a corrosion inhibitor, this can protect the armature construction before placing the repair material.

Water infiltration is one the main problem in the construction industry. They are generally caused by the deterioration of a surface, which consequently loses its waterproofing ability, or by a failure in the waterproofing capacity of the surface. The consequences of water infiltration may be only “aesthetic”, such as the separation and detachment of the painting, the formation of spots and streaks of moisture, mold and efflorescence, or, in severe cases, it can cause real structural problems, accelerating the degenerative process of building materials.

The design and choice of the best solution for waterproofing a surface, therefore, is a key aspect to ensure the maximum possible duration of the buildings, reducing to a minimum the maintenance required.

A first and important distinction between the different types of waterproofing is the intervention in presence of positive thrust and the ones with negative pressure, or counter-thrust.

Waterproofing with positive thrust

This category includes all interventions in which it is possible to operate on the surface directly in contact with the infiltration. This type of intervention is aimed at preventing the absorption of water by the whole structure. Practical examples of this category are: waterproofing of terraces and balconies, roofs, foundation walls before backfilling, liquid containment tanks, tubs, swimming pools.

Waterproofing with negative pressure

This category includes interventions in which you cannot operate on the surface directly in contact with the infiltration, and is therefore necessary to intervene on the surface on which infiltration occurs, blocking the leakage of water or moisture. Examples of this category are: waterproofing of basements and cellars and waterproofing of walls with the ground.

You should always consider that a positive thrust waterproofing allows to preserve the entire structure by absorption of water and its consequences, while the waterproofing with negative pressure can block the escape of water or moisture, but do not prevent the structure absorbing water.

Proposed Solutions

Positive Pressure Waterproofing

The waterproofing positive momentum involves creating a layer of waterproof material and is applied directly on the surface to be sealed , either flat, sloping or vertical . Regardless of the sealing ability of the material required to create sufficient flow for proper water drainage is essential.

Especially in the case of very large areas of intervention, a key feature is undoubtedly the elasticity of the sealing layer to be achieved. An elastic sealing layer will be able to cope with expansion movements without damage or cracks that inevitably will allow water to leak.

Another very important aspect to consider is the sequel to the sealing layers. Traditional technologies based on the use of bituminous membranes, which have many overlaps and joints due to the difficulty of setting and the great damage from the effects of cooling – heating, have major problems disordering connections and water penetration.

The ease of application of a sealant should be linked to: minimize the possibility of error from the installer and the application should be simple and fast, contributing to the success of the end result.

Suggested Solution

The sealers of positive pressure should be characterized by the ease of use ( by brush or roller ) and the high elasticity of the layer, due to the high amount of resin compared to the cementitious ones. For each application there are corresponding materials in order to have a better and cheaper solution.

Negative Pressure Waterproofing

Often the water penetration can not be solved by acting directly on the surface on which the filtration takes place, but only from the surface where there are the results in the form of spots and streaks of moisture or water penetration as cellars, basements, elevator , walls and floors etc.

Suggested Solution

The material to be used for sealing negative pressure must have, apart from the sealing ability, very high adhesion to the substrate. The product for sealing negative pressure should create a continuous and uniform layer of sealing. The high adhesion and the easy implementation (with a roller) to permit the use of multiple solutions of thickness up to 5 mm, depending on the needs of the application.

Waterproofing Joints – Cracks

For the success of the seal must ensure waterproofing of critical points such as vertical and horizontal joints, expansion joints and cracks that there is a possibility of water filtration, and therefore should be treated and sealed with the maximum care and attention.

Suggested Solution

The seal should be strong, durable and have the possibility of easy filling and resistance to ultraviolet rays and weather conditions, by the use of suitable sealing bars and strips (depending on the needs of the application).

Commercial or Private Concrete Floors – Manholes etc.

The cement floors are mainly found in industrial sites, workshops, garages, etc, where there are often problems peeling, cracking, potholes etc. These damages not only influence the appearance of the floor, but can jeopardize even the correct and safe passage of humans and vehicles, forklifts and trucks. Also if not corrected immediately, tend to increase rapidly their dimensions and extending over the entire surface of the floor.

It is important to repair the cracks of cement floors in the initial stage with such materials which will ensure high mechanical strength, even at low thickness, in order to restore in proper manner the surface, allowing the passage of people and vehicles.

Another important aspect to be considered in an intervention of this kind is surely the time required for the implementation and the ease of application of materials to avoid any interruption of work activities and production.

Solutions

- In most cases the use of a thixotropic cementitious materials fast curing with high strength can provide immediate and effective solution within 15 to 30 minutes, if necessary. In problems involving manholes, water gutters and metal structures together with concrete or asphalt, the use of specific repair materials can give long term solutions.

- In specific cases where good adhesion, resistance to chemicals, oils, salt water etc, the repair materials should be specific filling products for rehabilitation.

- For the restoration of cracks are particularly suitable epoxies sealing materials according to the size and depth of the crack.

Condensation is caused by the relative humidity inside a room which, in contact with a cold surface such as a wall not insulated, changes itself from gas to liquid. Consequently, the wall will be wet and therefore will be created the conditions favourable for:

- the formation of mold or efflorescence

- speeding up of the degenerative processes of materials such as plaster and paint

- conditions that are potentially harmful to human health

The presence and the formation of condensation in a building is an unavoidable aspect that cannot be completely deleted. It is possible, however, to create favorable conditions for its proper disposal or limit the amount within the limits suitable for good living conditions.

Solution

“Treatment” condensation on interior walls

Effective response compaction is done by coating the wall at points of moisture or mold with a special non- absorbent natural dye reduction of thermal bridges (warming cold spots in the walls). The coating should be up to 2 mm thick to allow easy repair. The application must improve the surface temperature 4-5 degrees Celsius, creating a white surface that can be covered by a traditional color for interiors.

Thereby drastically reduced and even completely eliminate, the condensation of moisture in the wall, eliminating the root cause of the creation of moisture, with a physical and not chemical solution.

This solution should have a number of advantages such as:

- Easy, cheap and fast application that can be done without the use

- experienced craftsman

- The new white surface can remain or be painted using

- based paint water.

- The immediate upgrading of sanitary living spaces

- The final solution with natural materials and non-toxic solvents