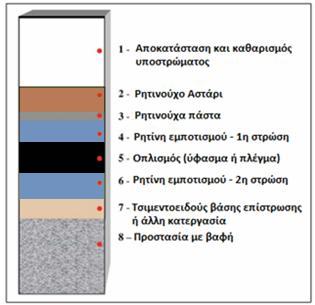

GENERAL STEPS FOR IMPLEMENTATION OF FABRICS – GRIDS – STRIPS USING RESINS:

The resins ARMOFIX by DRACO in combination with mesh reinforcement can be used on substrates of concrete, masonry, or wood. The applications include the following general steps:

Substrate Preparation

The purpose of preparing the substrate is the smoothing of the surface to aid in order to remove any failures to achieve the optimal and uniform adhesion of composite materials. Generally, the substrate is prepared by removing loose, damaged, and degraded parts. Shall be cleaned by sandblasting, water blasting or other suitable mechanical means to be free of grease, dust, or other materials. Also, the surface must be flat and smooth without voids or cavities. Any repairs to the flatness of the substrate are made using fine cement mortar. If there are cracks in the concrete must be restored by the process of resin injections. In damaged structural members, the restoration of concrete areas can be done with suitable high-strength mortars REPAR TIX by AZICHEM.

Mixing the Resins

The mixing of the two components [hardener (component B) is added into the resin (component A)] is done with a spatula or other hand tool, until a uniform mixture. The mixing ratio of the two components by weight is indicated in the table of characteristics of the resins.

Application Procedure

- Apply the primer layer with brush, roller, or brush, depending on the application. Where further smoothing and shaping of the surface is needed use resin pastes or repair mortars such as REPAR SM by AZICHEM, depending on the application.

- If needed, apply the first layer of adhesive resin impregnation with brush, squeeze, or roller directly onto the dry layer of the resin primer.

- Application of fabric / mesh / strip over the surface of the primed substrate, after unwound and stretched.

- Application of adhesive resin impregnation.

- For applying extra layers repeat steps 3-4.

- Finishing can be completed by using sandblasting on the fresh resin to prepare the surface for the application of subsequent coatings and to protect DRACO FRP ARMO SYSTEM from external factors (such as sunlight).

The application of laminates includes preparation of the substrate, as described. The surface of the plate is cleaned with a suitable solvent or remove, if available, the thin tape protection. Then the plate is welded to the substrate by using resin. For proper adhesion is necessary to pressure on the lamina in all directions in order to prevent air to be trapped between the paste and the concrete.

GENERAL STEPS FOR CRACK FILLING

The resins ARMOFIX by DRACO and produced to be used for injection for filling, sealing and anchoring cavities and cracks on all components of concrete structures. The application of filling cracks in the concrete ensures complete restoration and re-building element to its original condition.

- For cracks 0.1 mm – 5.0 mm thickness is proposed to use resin mechanically application.

- The surface sealing of cracks can be made by using resin paste.

REQUIRED EQUIPMENT FOR THE PLACEMENT OF COMPOSITE MATERIALS FIBER REINFORCEMENT POLYMERS (FRP)

The installation of composite materials (FRP) using resins requires:

Personal protective equipment:

- Professional clothing (coveralls, boots)

- Disposable Latex Gloves

- Multipurpose paper roll

- Mask and goggles

Tooling Materials:

- Electronic scale with accuracy of a gram

- Polyethylene plastic containers of 1 and 2 lt

- Acetone

- Brushes (width of 5 cm)

- Rolls (width of 10 cm)

- Cutting Scissors

- Cutter

- Spatula (width 3 cm and 5 cm)

- Aluminum Ruler (width 5-10 cm, length 3 m)

- Two wooden shelves for workbenches (dimensions 0,6 m x 2,00 m) and a wooden shelf as a cutting board (dimensions 0,6 x 3,00 m)

Minimum number of employees: 2 (Skilled technician and a laborer)